Hat Patches & Printing

Vinyl Fire offers multiple professional methods for customizing hats, allowing us to match the right process to your design, material, and intended use. From clean printed graphics to premium engraved patches, we produce hat decoration that looks sharp and holds up.

All hat patches and transfers are produced and finished in-house in North Idaho for consistent quality and reliable results.

You’ve got options.

DTF transfers allow full-color designs to be applied directly to hats with excellent detail and durability. This method is ideal for complex artwork, gradients, and small production runs.

Common uses:

Full-color logos, detailed artwork, short runs, multi-color designs

Direct To Film (DTF / Full Color)

Designed for hard-to-stick surfaces, our high tack stickers use an aggressive adhesive that holds strong where standard stickers won’t. Ideal when durability and adhesion matter most.

Use case: Low energy surfaces, hard hats, textured surfaces, machinery, industrial environments

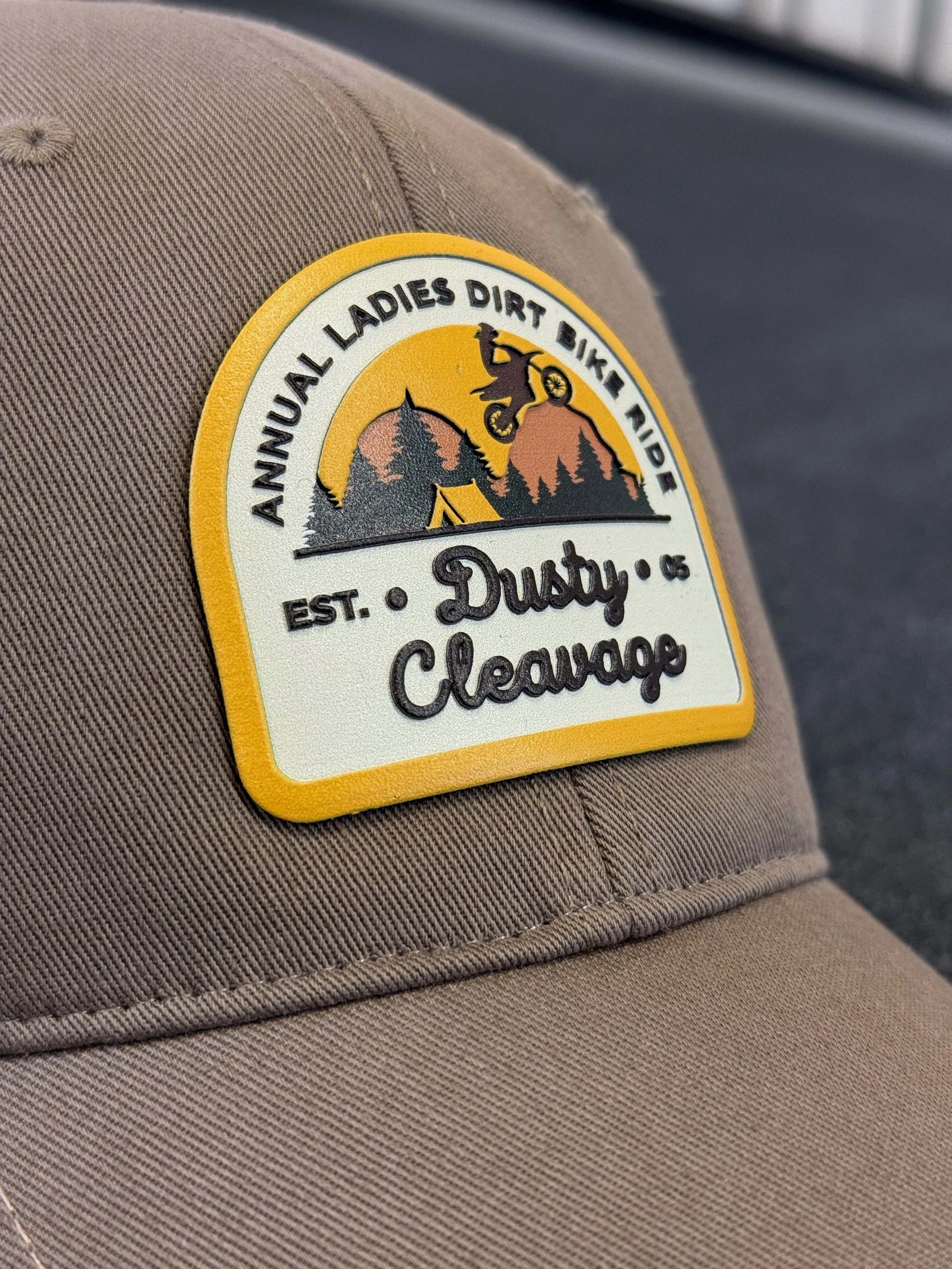

UV Printed Patches (Full Color)

Laser Engraved Leatherette Patches

Leatherette patches are laser engraved for a clean, consistent look that mimics real leather. These patches are finished with Lonestar® adhesive for a strong, permanent bond.

Common uses:

Branded hats, promotional merchandise, uniforms, retail product

Genuine leather patches are laser engraved for a premium, rugged finish. Each patch develops its own character, making it a popular option for higher-end branding. Finished with Lonestar® adhesive for reliable, long-term hold.

Common uses:

Premium hats, outdoor brands, lifestyle apparel, retail collections